EV Battery Swapping: Advantages, Disadvantages, and the Nepal Scenario

Najam Rain

August 24, 2025

Unlike the rapid refueling process of internal combustion engine (ICE) vehicles, recharging an EV battery typically requires 30 minutes to several hours. To mitigate this critical drawback, the automotive industry has seen the emergence of battery swapping technology (BST). BST provides a mechanism to exchange a depleted battery pack with a fully charged one in a matter of minutes, effectively bridging the convenience gap between EVs and ICE vehicles.

1. The Operational Procedure of Battery Swapping

The battery swapping process is a streamlined, multi-step procedure that integrates vehicle-to-infrastructure (V2I) communication with automated or semi-automated hardware systems. The standard operational flow can be broken down into the following key phases:

I. Authentication and V2I Communication

The process begins with the driver initiating a battery swap request through a dedicated mobile application or a similar telematics platform. This application serves as the primary interface for authenticating the vehicle and the user. It validates critical parameters such as the vehicle's current State of Charge (SOC), geographical location, and usage history. Furthermore, the application manages the user's subscription, payment processing, and billing, ensuring a seamless transaction and service delivery.

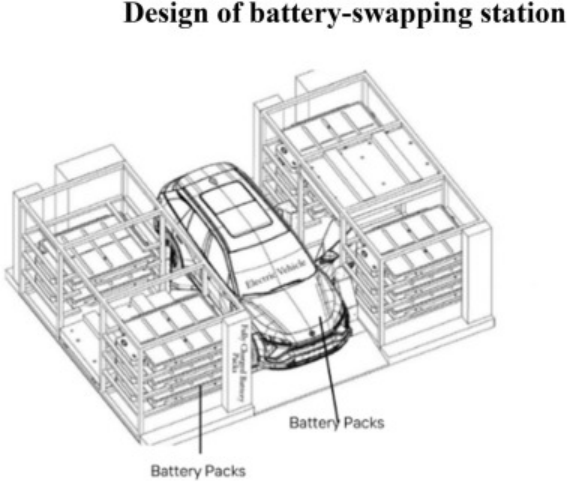

II. Physical Exchange of Battery Packs

Upon arrival at the swapping station, the vehicle is precisely positioned. The physical exchange of battery packs can vary in its degree of automation based on the vehicle type and the system architecture.

1.Two-Wheelers: For vehicles like those from the Gogoro brand, the process is often semi-automated or manual. The user physically removes the depleted, lightweight battery pack and places it into a designated slot within the swapping station. The system then releases a fully charged pack for the user to install.

2. Four-Wheeler's: For heavier vehicles, such as those from NIO, the process is fully automated. The vehicle self-parks into the designated swapping bay. Robotic arms or specialized machinery then autonomously unfasten and disconnect the high-voltage (HV) and low-voltage (LV) connections, including those for the Battery Management System (BMS). The discharged pack is removed and a fresh, charged pack is automatically fitted into the vehicle's chassis.

III. System Verification and Integration

Once the new battery is secured, the vehicle's onboard systems conduct a rapid diagnostic check. This verification protocol confirms the successful installation of the new battery pack and validates critical operating parameters, including the new SOC, temperature, and the integrity of all electrical and mechanical connections. This step ensures that the vehicle is safe and ready for operation with the new power source.

IV. Departure and Back-end Operations

After the successful completion of the system diagnostics, the driver is notified via the application. The transaction data, including the new battery's unique identifier and its characteristics, are securely stored in a cloud-based database. Simultaneously, the removed, depleted battery is moved to a dedicated charging stall within the station to be recharged for the next customer, completing the cycle of the battery-as-a-service (BaaS) model.

2. Advantages of Battery Swapping

Battery swapping technology offers compelling advantages that address some of the most critical challenges hindering the mass adoption of electric vehicles.

i. Reduction in Upfront Purchase Cost

Battery swapping operates on a Battery-as-a-Service (BaaS) business model. Under this paradigm, the customer purchases the EV chassis and its components, while the battery pack—the most expensive part of the vehicle—is acquired under a subscription or lease plan. This separation of the battery from the vehicle's initial price can significantly decrease the upfront cost by as much as 40% to 50%, making EVs more financially accessible and competitive with traditional internal combustion engine (ICE) vehicles. The service provider, in turn, bears the responsibility for battery management and maintenance, a cost which is factored into the recurring subscription fee.

ii. Drastically Reduced Downtime and Optimized Space Utilization

A core benefit of BST is its ability to reduce vehicle downtime from hours to a matter of minutes. While conventional Level 2 charging can take several hours (e.g., 5-6 hours for a two-wheeler) and even DC fast charging requires a minimum of 30 minutes, a battery swap can be completed in as little as 3-5 minutes. This near-instantaneous process eliminates the need for vehicles to wait in long queues at charging stations, a major operational inefficiency. Furthermore, battery swapping stations are more space-efficient than large charging hubs, as batteries can be stored and charged vertically, requiring minimal parking area for the actual swap.

iii. Elimination of Battery Ownership Risks

In a traditional EV ownership model, the customer is fully responsible for the battery's health, degradation, and eventual replacement, which can lead to significant long-term costs and consumer anxiety. With a BaaS model, the service provider assumes all responsibility for the battery's performance and lifespan. This means customers are absolved of concerns regarding State of Health (SOH), capacity degradation, and warranty complexities. The service provider's centralized management of battery assets ensures optimal charging conditions and maintenance, which can prolong the battery's overall lifecycle and improve its safety, a benefit that is passed on to the customer in the form of a reliable and consistent service.

3. Challenges & Limitations

Despite its potential to solve EV range anxiety, the widespread adoption of battery swapping technology is hindered by several significant limitations. These challenges span from infrastructure and interoperability to consumer perception and economic viability.

i. Infrastructure and Economic Viability

The primary limitation of BST is the capital-intensive nature of infrastructure development. Establishing a network of battery swapping stations requires a massive initial investment. A single swapping station, with its complex robotics, climate-controlled storage, and sophisticated power management systems, costs significantly more than a standard DC fast-charging station. This high cost of entry limits the number of stations, leading to a fragmented and geographically sparse network. Consequently, customers still face the challenge of range anxiety due to the limited availability of swap locations.

ii. Lack of Standardization and Interoperability

A major technical and commercial hurdle is the lack of battery pack standardization. Unlike a universal charging protocol like GB/T or CCS, which allows a single fast charger to serve multiple EV brands, a battery swapping station is typically designed for a specific vehicle model or a single manufacturer. This brand-specific dependency means that an investment in a swapping station yields a return from only a limited subset of the market, unlike a generic fast charger that can serve any compatible EV. This lack of interoperability poses a major barrier to widespread adoption and market consolidation.

iii. Consumer Ownership and Trust

From a consumer perspective, BST introduces a nuanced challenge related to ownership and trust. When a battery is swapped, the customer gives up their original battery pack in exchange for a different one. This process can lead to ownership dissonance, where the user may feel a loss of control over a critical component of their vehicle. Concerns about the integrity and performance of the swapped battery, such as its State of Health (SOH), age, and charging history, can create uncertainty and erode consumer confidence. This psychological barrier can be a significant deterrent, even if the service is otherwise efficient.

4. Battery Swapping in Nepal

Gogoro, in partnership with Nebula Energy, has successfully launched its battery swapping network in Kathmandu, Nepal. The strategy focuses on rapid infrastructure deployment, with 45 swapping stations already operational across key urban and commercial hubs like Kamalpokhari, Pulchowk, and Chabahil. This robust network ensures that riders can instantly swap depleted batteries for fully charged ones, eliminating the long waits of traditional charging. By providing seamless and ubiquitous access to power, Gogoro aims to mitigate range anxiety and accelerate the adoption of electric scooters in the Nepalese market.

While Nepal has seen high adoption of electric four-wheelers, the electric two-wheeler market lags significantly due to major drawbacks: long charging times (5-6 hours for an average 60-70 km range) and limited range. Gogoro's battery swapping model is a promising solution to these issues, enabling near-instantaneous power replenishment. However, the high cost of building swapping stations currently confines this technology to urban centers like Kathmandu, making it an excellent solution for intra-city commutes but not yet a feasible option for long-distance travel

You may also like

EV

April 17, 2025

Building Nepal’s EV Ecosystem: The Role of Infrastructure, Training, and Policy Support

EV

April 30, 2025

Nepal’s Surge in Electric Vehicle Imports: A Rs 12.73 Billion Journey.

EV

July 11, 2025